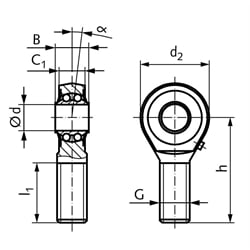

Rod end BR DIN ISO 12240-4 series K external tread M22x1.5 left with spherical ball bearing

| Thread | links |

|---|---|

| d H7 [mm] | 22 |

| B-0,1 [mm] | 28 |

| C1 [mm] | 20,0 |

| d2 [mm] | 54 |

| h [mm] | 84 |

| l1 [mm] | 51 |

| Thread Size d3 [mm] | M22x1,5 |

| Thread Slope[mm] | 1,5 |

| Tipping Angle Alpha [°] | 8,0 |

| Load Rating dyn. C [k N] | 9,3 |

| Load Rating stat. Co [k N] | 4,0 |

| Calc. Factor X | 2,35 |

| Calc. Factor Yo | 2,24 |

| Speed n max. [rpm] | 725 |

| Weight [g] | 391 |

Material: Outer part: Alloyed steel, forged, quenched and tempered. Bearing race hardened, ground and lapped. Thread rolled., Surface zinc-plated and chromatised. Inner ring: Roller bearing steel, hardened, ground and polished. Lubrication: Aluminium-complex-soap-grease, approval according to NSF H1, -45ºC to +120ºC. Wide version. Dimensions according to DIN ISO 12240-4 (DIN 648) series K. Thread either right-handed or left-handed.

- Heavy-duty rod ends with roller bearing.

- very light running (basically without friction).

- Long-term lubricated and sealed with cover plates.

- For high loads.

These rod ends are not suitable for applications with high safety requirements, e.g. in aircraft.

Note: The specific loading of rod ends and spherical-plain bearings differs in each application. Therefore general statements by a producer in a catalogue may not totally fit to the single application. In all cases the user has to coordinate the theoretical selection criteria with the concrete installation situation and check the suitability of the rod end respectively spherical-plain bearing. In this context the user has to define sufficient security factors and maintenance intervals.