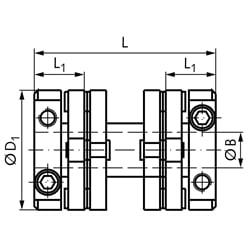

Membrane coupling MEM with clamping hub bore both sides 6mm max. torque 2.3Nm

| Torque max. [Nm] | 2,3 |

|---|---|

| Bore +0,03-0 [mm] | 6 |

| L [mm] | 36,1 |

| L1* [mm] | 10 |

| D1 [mm] | 25,6 |

| Max. Displacement [±°] | 4 |

| Max. Displacement radial [±mm] | 0,4 |

| max. Misalignment axial [±mm] | 0,2 |

| Torsional Rigidity [Nm/rad] | 400 |

| Weight [g] | 25 |

Materials: Hubs and sleeves: Aluminium alloy 2011T3 and 2011T8 BS 4300/5 FC1, clear anodised finish. Membranes: stainless high-quality spring steel. Screw connection: Screws: heat-treated steel, black oxide finish. Bushes: Steel zinc-plated and chromated black. Connecting parts: Heat-treated steel, black oxide finish. Temperature range: -40°C to +120°C. Torsionally-stiff construction, no moving parts, all-metal design, low moment of inertia. The functional principle offers the highest operational readiness to be achieved with flexible couplings. Excellent kinematic properties and high torsion-spring stiffness. Suitable for servo drives. Tolerant flexural system and a dynamically balanced construction for high-end positioning and servo drives. Operating Factors: Type of Load - Operating Factor Uniform Load - 1,5 Alternating Load - 2 Shock load - 3 Reversing shock load - 4 *depth of bore, remaining length relieved.