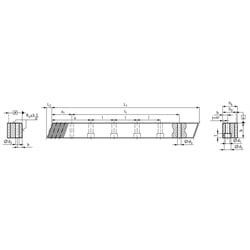

Precision gear rack made of bright steel 900N/mm² module 5 500mm long with bores

| L1 [mm] | 500 |

|---|---|

| Type | mit Bohrungen |

| L2 [mm] | 17,4 |

| No. of Teeth | 30 |

| b [mm] | 50 |

| hk [mm] | 39 |

| h0 [mm] | 34 |

| f [mm] | 3 |

| a [mm] | 62,50 |

| l [mm] | 125 |

| No. of Bores | 4 |

| h [mm] | 12 |

| d1 [mm] | 14 |

| d2 [mm] | 20 |

| t [mm] | 13 |

| a1 [mm] | 37,5 |

| l1 [mm] | 425,0 |

| d3 [mm] | 11,7 |

| GTf / 300* [mm] | 0,050 |

| Fu** [N] | 15000 |

| Weight | 6,50 |

Material: High-quality, specially treated bright steel with approx. 900 N/mm² tensile strength. Helical tooth system, right hand 19° 31' 42''. Milled teeth, tooth quality 8e27. For continuous linking. See also the matching left hand-toothed counterparts to simplify the mounting. Note: These right-handed racks are designed to be used in combination with our helical-toothed left-handed gears. 1) GTf /300 = total pitch error, i.e. the max. permissible deviation (per 300 mm) of the measured length of the rack compared to the theoretical length L300, with L300 = (m / cos ß) * p * z300). *Tangential force at tooth, calculated for z = 20. With a smaller number of teeth, the tangential force has to be reduced by 10%.