Tensioning Elements, Zinc-Plated and Oil Resistant

Material: Casing made of sintered steel or grey cast iron GG20, lever made of St52.

The design of these tensioning elements is identical to the standard version, but they are zinc-plated and the synthetic spring elements are resistant to mineral oils. These components are especially suited for 'outdoor' applications, e.g. for construction machinery or for use inside the oilbath of a gearbox. The tensioning elements are marked with a yellow dot on the lever. Can be used for both tensioning directions.

Temperature range: -30°C to -90°C.

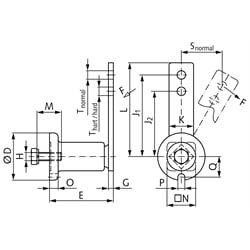

| SKU | Size | F max. at normal [N] | F max. at hard [N] | s max. normal [mm] | s max. hard [mm] | D [mm] | E [mm] | G [mm] | H [mm] | J1 [mm] | J2 [mm] | K [mm] | L [mm] | M [mm] | N [mm] | O [mm] | P [mm] | Q [mm] | T [mm] | MA [Nm] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 14080003 | 0 | 96 | 128 | 40 | 30 | 35 | 51 +1,0 -0,5 | 5 | M6 | 80 | 60 | 20 | 90 | 20 | 22 | 6 | 8 | 16,5 | 8,5 | 10 | 0,2 |

| 14080103 | 1 | 135 | 170 | 50 | 40 | 45 | 64 +1,0 -0,5 | 5 | M8 | 100 | 80 | 25 | 112,5 | 25 | 30 | 8 | 8,5 | 20,8 | 10,5 | 25 | 0,4 |

| 14080203 | 2 | 350 | 440 | 50 | 40 | 58 | 79 +1,5 -0,5 | 7 | M10 | 100 | 80 | 30 | 115 | 30 | 35 | 10,5 | 8,5 | 25,3 | 10,5 | 49 | 0,6 |

| 14080303 | 3 | 810 | 1050 | 65 | 50 | 78 | 108 +2,0 -0,5 | 8 | M12 | 130 | 100 | 50 | 155 | 40 | 52 | 15 | 10,5 | 34,3 | 12,5 | 86 | 1,7 |

| 14080403 | 4 | 1500 | 1875 | 87,5 | 70 | 95 | 140 +2,0 -0,5 | 10 | M16 | 175 | 140 | 60 | 205 | 40 | 66 | 15 | 12,5 | 42,0 | 20,5 | 210 | 3,55 |