Shrink Disks ST

Material: High quality steel 42CrMo4.

- For fixing a hub (e.g. drive wheel, rotor or similar) on a shaft.

- For medium torques.

- Quick mounting.

- Quick dismounting.

- No axial offset during mounting.

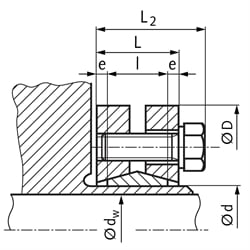

Roughness: max, RZ=16 μm. Outer-Ø tolerance of hub = h9.

Recommended tolerances for hub bore / shaft diameter: from dw Ø 30 = H6/j6; Ø 31-50 = H6/h6; Ø 51-65 = H6/g6.

It is essential to degrease the contact surfaces of shaft and hub bore. Lubricate only the shrink disk and the screws with MoS2 and place it on the hub. Turn in the screws evenly by hand. Surface Roughness, Tolerances and Mounting Fasten the tensioning screws evenly, in sequence (not crossing over) until the fastening torque TA of the table is reached. To reach the value of TA, several fastening steps are required. The figures for T stated in the table were calculated for a lubricated shrink disk.

Do you have a clamping set with a foreign designation?

Recode it here in our exchange Tool

| SKU | Inner Ø d [mm] | Shaft Ø dw [mm] | Torque Mt [Nm] | D [mm] | L [mm] | L2 [mm] | l [mm] | e [mm] | Clamping Bolts DIN 931 - 10.9 [N. x Typ] | Torque Ms [Nm] | Surface Pressure pw [N/mm²] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 61581400 | 14 | 10 - 12 | 40- 65 | 38 | 15 | 18,5 | 10 | 2,5 | 4 x M5 x 12 | 3 | 154 - 243 | 0,10 |

| 61581600 | 16 | 12 - 14 | 65 - 95 | 41 | 17 | 20,5 | 12 | 2,5 | 5 x M5 x 16 | 3 | 108 - 190 | 0,14 |

| 61581800 | 18 | 14 - 16 | 85 - 130 | 44 | 17 | 20,5 | 12 | 2,5 | 4 x M5 x 16 | 4 | 172 - 233 | 0,15 |

| 61582000 | 20 | 15 - 17 | 110 - 150 | 46 | 17 | 20,5 | 12 | 2,5 | 5 x M5 x 16 | 4 | 205 - 258 | 0,17 |

| 61582100 | 21 | 16 - 18 | 180 - 270 | 50 | 20 | 23,5 | 14 | 3,0 | 6 x M5 x 18 | 5 | 220 - 275 | 0,23 |

| 61582400 | 24 | 19 - 21 | 220 - 330 | 50 | 20 | 23,5 | 14 | 3,0 | 6 x M5 x 18 | 5 | 189 - 228 | 0,22 |

| 61583000 | 30 | 24 - 26 | 350 - 470 | 60 | 22 | 25,5 | 16 | 3,0 | 7 x M5 x 18 | 5 | 159 - 184 | 0,33 |

| 61583600 | 36 | 28 - 31 | 730 - 880 | 72 | 23,5 | 27,5 | 18 | 2,75 | 5 x M6 x 20 | 12 | 232 - 250 | 0,52 |

| 61583800 | 38 | 29 - 31 | 710 - 760 | 72 | 23,5 | 27,5 | 18 | 2,75 | 6 x M6 x 20 | 12 | 198 - 211 | 0,50 |

| 61584000 | 40 | 30 - 32 | 770 - 825 | 72 | 23,5 | 27,5 | 18 | 2,75 | 6 x M6 x 20 | 12 | 216 - 230 | 0,50 |

| 61584400 | 44 | 32 - 36 | 1200 - 1500 | 80 | 25,5 | 29,5 | 20 | 2,75 | 7 x M6 x 20 | 12 | 225 - 244 | 0,64 |

| 61585000 | 50 | 38 - 42 | 1500 - 2100 | 90 | 27,5 | 31,5 | 22 | 2,75 | 8 x M6 x 25 | 12 | 204 - 232 | 0,87 |

| 61585500 | 55 | 42 - 48 | 1700 - 2600 | 100 | 30,5 | 34,5 | 23 | 3,75 | 8 x M6 x 25 | 12 | 176 - 210 | 1,18 |

| 61586200 | 62 | 48 - 52 | 2700 - 3200 | 110 | 30,5 | 34,5 | 23 | 3,75 | 10 x M6 x 25 | 12 | 213 - 222 | 1,41 |

| 61586800 | 68 | 50 - 60 | 2500 - 4100 | 115 | 30,5 | 34,5 | 23 | 3,75 | 10 x M6 x 25 | 12 | 184 - 212 | 1,46 |

| 61587500 | 75 | 55 - 65 | 3500 - 6000 | 138 | 32,5 | 37,8 | 25 | 3,75 | 7 x M8 x 30 | 30 | 199 - 241 | 2,45 |