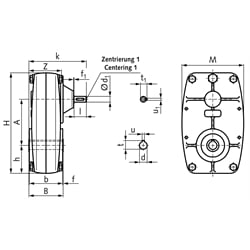

Shaft-Mounted Flat Gearboxes BOC1, 2-Stage, Size 1, Version A, up to 250 N

General data: Compact design for confined spaces. Ratios of i = approx. 3.34:1 to 55.79:1. Larger ratios on request. Input power of 0.68 to 8.4 kW Version A: With hollow shaft on output side = Standard. Version B: With torque arm. Version C: With flange on the output side. Version D: With foot mounting brackets, see drawing on PDF-catalog pages. Version E: With foot mounting brackets, see drawing on PDF-catalog pages. Version F: With single-sided solid output shaft. (Version B - F on request). Housing: Rigid, ribbed grey cast iron housing, thus quiet, lowvibration running characteristics. Fully sealed against oil leaks and protected against water jets. Gears: The helical gear wheels are made from heat-treated and case-hardened steel. The gearing is hardened and precisely machined. Bearing: Generously-dimensioned roller bearings. Input shaft/end shield: The shaft tolerances, and the flange adapters which can be delivered on request, are suited for IEC standard motors. Lubrication: The gear boxes are delivered ready for work, filled with the correct level of oil or grease (ambient temperature - 10°C to 50°C), which offers sufficient lubrication for about 10.000 operation hours, or for an operation period of max. 2 years. Before start up, the plastic plug must be taken out of the venting screw.

| SKU | Type | Ratio i | T2bei f B=1 [Nm] | n2bei n1=1400min¯¹ [min ¯¹] | Pbei n1=1400min¯¹ [k W] | Weight [kg] |

|---|---|---|---|---|---|---|

| 40030001 | A | 3,34 | 184 | 413,6 | 8,40 | 12,5 |

| 40030002 | A | 3,58 | 197 | 385,2 | 8,40 | 12,5 |

| 40030003 | A | 3,86 | 213 | 357,7 | 8,40 | 12,5 |

| 40030004 | A | 4,17 | 230 | 331,2 | 8,40 | 12,5 |

| 40030005 | A | 4,52 | 250 | 305,5 | 8,40 | 12,5 |

| 40030006 | A | 4,92 | 250 | 280,6 | 7,70 | 12,5 |

| 40030007 | A | 5,38 | 250 | 256,5 | 7,10 | 12,5 |

| 40030008 | A | 5,92 | 250 | 233,1 | 6,40 | 12,5 |

| 40030009 | A | 6,44 | 196 | 214,2 | 4,60 | 12,5 |

| 40030010 | A | 6,96 | 212 | 198,3 | 4,60 | 12,5 |

| 40030011 | A | 7,54 | 229 | 182,9 | 4,60 | 12,5 |

| 40030012 | A | 8,21 | 250 | 168,0 | 4,60 | 12,5 |

| 40030013 | A | 8,98 | 250 | 153,6 | 4,20 | 12,5 |

| 40030014 | A | 9,89 | 250 | 139,6 | 3,80 | 12,5 |

| 40030015 | A | 10,75 | 204 | 128,4 | 2,90 | 12,5 |

| 40030016 | A | 11,54 | 219 | 119,6 | 2,90 | 12,5 |

| 40030017 | A | 12,42 | 236 | 111,1 | 2,90 | 12,5 |

| 40030018 | A | 13,42 | 250 | 102,8 | 2,80 | 12,5 |

| 40030019 | A | 14,55 | 250 | 94,8 | 2,60 | 12,5 |

| 40030020 | A | 15,84 | 250 | 87,1 | 2,40 | 12,5 |

| 40030021 | A | 17,33 | 250 | 79,6 | 2,20 | 12,5 |

| 40030022 | A | 19,07 | 250 | 72,4 | 2,00 | 12,5 |

| 40030023 | A | 19,94 | 227 | 69,2 | 1,70 | 12,5 |

| 40030024 | A | 21,41 | 244 | 64,4 | 1,70 | 12,5 |

| 40030025 | A | 23,06 | 250 | 59,8 | 1,60 | 12,5 |

| 40030026 | A | 24,91 | 250 | 55,4 | 1,50 | 12,5 |

| 40030027 | A | 27,00 | 250 | 51,1 | 1,40 | 12,5 |

| 40030028 | A | 29,40 | 250 | 46,9 | 1,30 | 12,5 |

| 40030029 | A | 32,16 | 250 | 42,9 | 1,20 | 12,5 |

| 40030030 | A | 35,39 | 250 | 39,0 | 1,10 | 12,5 |

| 40030031 | A | 36,35 | 250 | 38,0 | 1,00 | 12,5 |

| 40030032 | A | 39,27 | 250 | 35,1 | 00,97 | 12,5 |

| 40030033 | A | 42,57 | 250 | 32,4 | 00,89 | 12,5 |

| 40030034 | A | 46,35 | 250 | 29,8 | 00,82 | 12,5 |

| 40030035 | A | 50,71 | 250 | 27,2 | 00,75 | 12,5 |

| 40030036 | A | 55,79 | 250 | 24,7 | 00,68 | 12,5 |