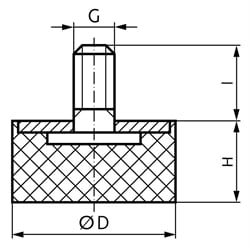

Rubber-Metal Bump Stop MGS with Threaded Stud, Zinc-plated

Material: Metal parts: Steel, zinc-plated. Elastomer: Natural rubber, black, hardness 55º +/-5º Shore A.

Metal on one side only. Metal bumpers can be used to limit bearing surfaces e.g. for elastically mounted power units, and as bump stop to limit the spring travel in vehicles. They can also be used for machines that cannot be fixed to the floor or are standing on floors with an easily damaged surface, e.g. office machines. * Fperm. is the permissible static permanent load, which may be overlaid by a dynamic, alternating load. With shearing load please take care that no tension load in the rubber occurs at all during mounting. To achieve a sufficient fatigue strength provide some compressive pre-stressing. The stated permissible loads are only approximate, guideline values for the static load for "medium" rubber hardness. With particularly high, dynamic, alternating loads or high frequencies, the load figures have to be reduced accordingly. Temperature resistant up to 80°C.

| SKU | D [mm] | H [mm] | G [mm] | I [mm] | Spring Rate CD average [N/mm] |

|---|---|---|---|---|---|

| 68578000 | 8 | 8 | M3 | 6 | 1,0 |

| 68578100 | 10 | 10 | M4 | 10 | 38 |

| 68578300 | 10 | 15 | M4 | 10 | 13 |

| 68578600 | 15 | 7 | M4 | 10 | 136 |

| 68578700 | 15 | 8 | M4 | 10 | 122 |

| 68578800 | 15 | 10 | M4 | 10 | 106 |

| 68579000 | 15 | 15 | M4 | 10 | 74 |

| 68579100 | 20 | 5 | M6 | 18 | 340 |

| 68580100 | 20 | 8 | M6 | 18 | 330 |

| 68580111 | 20 | 11 | M6 | 18 | 150 |

| 68580200 | 20 | 15 | M6 | 18 | 138 |

| 68580220 | 20 | 20 | M6 | 18 | 100 |

| 68580225 | 20 | 25 | M6 | 18 | 80 |

| 68580308 | 25 | 8 | M6 | 18 | 300 |

| 68580310 | 25 | 10 | M6 | 18 | 270 |

| 68580300 | 25 | 15 | M6 | 18 | 254 |

| 68580320 | 25 | 20 | M6 | 18 | 128 |

| 68580325 | 25 | 25 | M6 | 18 | 100 |

| 68580330 | 25 | 30 | M6 | 18 | 80 |

| 68580415 | 30 | 15 | M8 | 23 | 290 |

| 68580400 | 30 | 20 | M8 | 20 | 200 |

| 68580425 | 30 | 25 | M8 | 20 | 180 |

| 68580430 | 30 | 30 | M8 | 20 | 120 |

| 68580440 | 30 | 40 | M8 | 20 | 90 |

| 68580520 | 40 | 20 | M8 | 23 | 340 |

| 68580500 | 40 | 30 | M8 | 23 | 234 |

| 68580530 | 40 | 30 | M10 | 28 | 240 |

| 68580540 | 40 | 40 | M8 | 23 | 200 |

| 68580600 | 50 | 20 | M10 | 28 | 680 |

| 68580630 | 50 | 30 | M10 | 28 | 425 |

| 68580640 | 50 | 40 | M10 | 28 | 390 |

| 68580645 | 50 | 45 | M10 | 28 | 350 |

| 68580650 | 50 | 50 | M10 | 28 | 310 |

| 68580660 | 60 | 40 | M10 | 28 | 470 |

| 68580665 | 60 | 40 | M12 | 33 | 460 |

| 68580670 | 70 | 25 | M10 | 28 | 650 |

| 68580675 | 70 | 45 | M10 | 28 | 800 |

| 68580700 | 75 | 25 | M12 | 37 | 2000 |

| 68580740 | 75 | 40 | M12 | 37 | 810 |

| 68580750 | 75 | 50 | M12 | 37 | 620 |

| 68580755 | 75 | 55 | M12 | 37 | 760 |

| 68580820 | 100 | 20 | M16 | 42 | 2500 |

| 68580800 | 100 | 40 | M16 | 42 | 1578 |

| 68580850 | 100 | 50 | M16 | 42 | 900 |

| 68580855 | 100 | 55 | M16 | 42 | 860 |

| 68580860 | 100 | 60 | M16 | 42 | 800 |

| 68580875 | 100 | 75 | M16 | 42 | 540 |