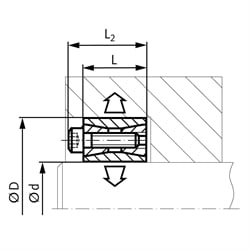

Locking Assemblies COM-A, QPQ coated, boreholes 14 - 50 mm

Material: Steel, QPQ coated. High corrosion resistance,improved fatigue strength, primarily food safe.

Clamping bush for medium high torques; not self-centering.

Fit: Shaft h8. Hub H8. Surface roughness hub/shaft Rz max. 12.5 µm.

Mounting: Slightly oil the clamping set before mounting, do not use molibdenum disulphide or grease. Tighten the screws evenly and crosswise in several steps.

Demounting: Due to the large cone angle, the clamping set releases on its own after the screws have been fully unfastened.

There are three larger threads cut into the front ring, which serve to remove this ring.

Ts - Fastening Torque

T - Transmittable Torque

F - Transmittable Axial Force

P - Surface Pressure onto Hub

QPQ Surface Properties: Very good corrosion resistance, betterthan hard chrome or chem. nickel. Corrosion resistance in the salt spraytest SS CASS in accordance with DIN 50021. Layer thickness of 10 - 25 µmpossible. For medium operational demands we recommend a layer thicknessof 15 µm at a 90 minute treatment. Only very small changes in dimensions(only 5 µm), as the surface modification is achieved through diffusionand not application. Surface hardness same as clamping set material =350 HV. Improved wear resistance, no fretting corrosion, no cold shut.Increased endurance strength, sometimes up to 100% higher. Is completelysafe to use with food as long as there is no contact with any acidicsubstances with a pH-value of = 4.

Do you have a clamping set with a foreign designation?

Recode it here in our exchange Tool

| SKU | d [mm] | D [mm] | L [mm] | L2 [mm] | Transmissible Torque T [Nm] | Transmissible Axial Force Fax [k N] | Surface Pressure Hub P [N/mm²] | Bolt Size M [mm] | Tightening Torque TA [Nm] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|

| 61577514 | 14 | 42 | 20 | 26 | 180 | 26 | 291 | 8 x M6 x 18 | 15 | 0,18 |

| 61577515 | 15 | 42 | 20 | 26 | 200 | 27 | 282 | 8 x M6 x 18 | 15 | 0,18 |

| 61577516 | 16 | 44 | 20 | 26 | 205 | 26 | 251 | 8 x M6 x 18 | 15 | 0,18 |

| 61577517 | 17 | 44 | 20 | 26 | 220 | 26 | 240 | 8 x M6 x 18 | 15 | 0,18 |

| 61577518 | 18 | 47 | 20 | 26 | 230 | 25 | 195 | 8 x M6 x 18 | 15 | 0,22 |

| 61577519 | 19 | 47 | 20 | 26 | 270 | 28 | 221 | 8 x M6 x 18 | 15 | 0,22 |

| 61577520 | 20 | 47 | 20 | 26 | 290 | 28 | 232 | 8 x M6 x 18 | 15 | 0,22 |

| 61577522 | 22 | 47 | 20 | 26 | 290 | 30 | 200 | 8 x M6 x 18 | 15 | 0,21 |

| 61577524 | 24 | 50 | 20 | 26 | 380 | 32 | 216 | 8 x M6 x 18 | 15 | 0,21 |

| 61577525 | 25 | 50 | 20 | 26 | 400 | 33 | 200 | 8 x M6 x 18 | 15 | 0,23 |

| 61577528 | 28 | 55 | 20 | 26 | 520 | 36 | 208 | 10 x M6 x 18 | 15 | 0,27 |

| 61577530 | 30 | 55 | 20 | 26 | 520 | 37 | 183 | 10 x M6 x 18 | 15 | 0,26 |

| 61577532 | 32 | 60 | 20 | 26 | 690 | 43 | 209 | 12 x M6 x 18 | 15 | 0,28 |

| 61577535 | 35 | 60 | 20 | 26 | 770 | 44 | 196 | 12 x M6 x 18 | 15 | 0,30 |

| 61577538 | 38 | 65 | 20 | 26 | 940 | 49 | 202 | 14 x M6 x 18 | 15 | 0,33 |

| 61577540 | 40 | 65 | 20 | 26 | 980 | 49 | 190 | 14 x M6 x 18 | 15 | 0,32 |

| 61577545 | 45 | 75 | 24 | 32 | 1700 | 74 | 216 | 12 x M8 x 22 | 37 | 0,55 |

| 61577550 | 50 | 80 | 24 | 32 | 1830 | 75 | 196 | 12 x M8 x 22 | 37 | 0,56 |