Locking Assemblies BAR, QPQ-Coated, boreholes 5 - 50 mm

- For fixing a hub on a shaft. - QPQ coated: High corrosion resistance, improved fatigue strength, primarily food safe (further information see below). - For medium torques. - Self-centering. - Slight axial offset possible during assembly.

Fit, Surface: Due to the special design of the BAR clamping set even rough fits can be bridged with excellent self centering capacity. Shaft and hub up to Quality h8/H8. Surface finish for shaft and hub Rz < 12 µm.

QPQ Surface Properties: Very good corrosion resistance, better than hard chrome or chem. nickel. Corrosion resistance in the salt spray test SS CASS in accordance with DIN 50021. Layer thickness of 10 - 25 µm possible. For medium operational demands we recommend a layer thickness of 15 µm at a 90 minute treatment. Only very small changes in dimensions (only 5 µm), as the surface modification is achieved through diffusion and not application. Surface hardness same as clamping set material = 350 HV. Improved wear resistance, no fretting corrosion, no cold shut. Increased endurance strength, sometimes up to 100% higher. Is completely safe to use with food as long as there is no contact with any acidic substances with a pH-value of = 4.

Do you have a clamping set with a foreign designation?

Recode it here in our exchange Tool

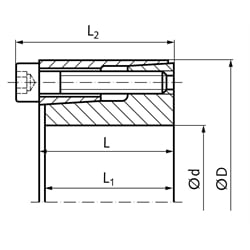

| SKU | d [mm] | D [mm] | L [mm] | L1 [mm] | L2 [mm] | M t (transferable at MA) [Nm] | P ax (at MA transferable) [k N] | Surface Pressure Shaft PW [N/mm²] | Surface Pressure Hub PN [N/mm²] | Clamping Bolts Size | Tightening Torque TA [Nm] | No. of Clamping Bolts | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 61570500 | 5 | 16 | 11 | 10,5 | 13,5 | 6 | 2 | 150 | 55 | M2,5 x 10 | 1,2 | 3 | 0,012 |

| 61570600 | 6 | 16 | 11 | 10,5 | 13,5 | 9 | 3 | 184 | 69 | M2,5 x 10 | 1,2 | 3 | 0,012 |

| 61570635 | 6,35 | 16 | 11 | 10,5 | 13,5 | 10 | 3 | 180 | 72 | M2,5 x 10 | 1,2 | 3 | 0,012 |

| 61570800 | 8 | 18 | 11 | 10,5 | 13,5 | 12 | 3 | 141 | 62 | M2,5 x 10 | 1,2 | 3 | 0,015 |

| 61570900 | 9 | 20 | 13 | 12,5 | 15,5 | 17 | 4 | 132 | 60 | M2,5 x 12 | 1,2 | 4 | 0,020 |

| 61571000 | 10 | 20 | 13 | 12,5 | 15,5 | 19 | 4 | 120 | 60 | M2,5 x 12 | 1,2 | 4 | 0,019 |

| 61571100 | 11 | 22 | 13 | 12,5 | 15,5 | 21 | 4 | 108 | 54 | M2,5 x 12 | 1,2 | 4 | 0,024 |

| 61571200 | 12 | 22 | 13 | 12,5 | 15,5 | 24 | 4 | 102 | 55 | M2,5 x 12 | 1,2 | 4 | 0,022 |

| 61571400 | 14 | 26 | 17 | 16,5 | 20,0 | 40 | 6 | 94 | 50 | M3 x 16 | 2,1 | 4 | 0,039 |

| 61571500 | 15 | 28 | 17 | 16,5 | 20,0 | 44 | 6 | 93 | 50 | M3 x 16 | 2,1 | 4 | 0,044 |

| 61571600 | 16 | 32 | 17 | 16,5 | 21,0 | 86 | 10 | 158 | 79 | M4 x 16 | 4,9 | 4 | 0,067 |

| 61571700 | 17 | 35 | 21 | 20,5 | 25,0 | 88 | 10 | 116 | 56 | M4 x 20 | 4,9 | 4 | 0,090 |

| 61571800 | 18 | 35 | 21 | 20,5 | 25,0 | 94 | 11 | 110 | 57 | M4 x 20 | 4,9 | 4 | 0,087 |

| 61571900 | 19 | 35 | 21 | 20,5 | 25,0 | 99 | 11 | 104 | 56 | M4 x 20 | 4,9 | 4 | 0,080 |

| 61572000 | 20 | 38 | 21 | 20,5 | 26,0 | 179 | 17 | 169 | 89 | M5 x 20 | 10 | 4 | 0,100 |

| 61572200 | 22 | 40 | 21 | 20,5 | 26,0 | 187 | 18 | 146 | 90 | M5 x 20 | 10 | 4 | 0,110 |

| 61572500 | 25 | 47 | 26 | 25 | 32,0 | 300 | 24 | 147 | 78 | M6 x 25 | 17 | 4 | 0,190 |

| 61573000 | 30 | 55 | 26 | 25 | 32,0 | 510 | 32 | 174 | 95 | M6 x 25 | 17 | 6 | 0,270 |

| 61573500 | 35 | 60 | 31 | 30 | 37,0 | 820 | 47 | 172 | 100 | M6 x 30 | 17 | 8 | 0,360 |

| 61573800 | 38 | 65 | 31 | 30 | 37,0 | 880 | 47 | 157 | 92 | M6 x 30 | 17 | 8 | 0,430 |

| 61574000 | 40 | 65 | 31 | 30 | 37,0 | 1000 | 50 | 171 | 99 | M6 x 30 | 17 | 8 | 0,400 |

| 61575000 | 50 | 80 | 36 | 35 | 44,0 | 2150 | 89 | 190 | 118 | M8 x 35 | 41 | 8 | 0,700 |