Internal Freewheels TFS

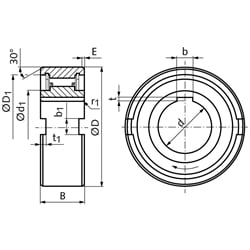

These sprag freewheels without own bearing support in premium quality can be used as indexing freewheels, backstops or overrunning clutches. They allow a compact design and are installed in housings provided by the customer. The user must ensure proper bearings, lubrication and sealing during installation. Radial forces are not permitted. The nominal dimensions d x D correspond to the dimensions of ball bearing series 63, except for TFS 12. With keyway on the inner ring and two radial, face-side grooves on the outer ring on both sides.

Keyway: The keyway is up to diameter d=12mm according to DIN 6885-1. Above that according to DIN 6885-3.

Mounting: For the bearing and the freewheel, the same installation tolerances must be provided. Recommended housing tolerance H7. For the shaft h7. If the tolerance of the housing inner diameter for the freewheel TFS is K6, no feather keys are required on the end face grooves of the freewheel. During installation, care must be taken to ensure the correct direction of rotation. The direction of rotation is indicated by a marking arrow on the freewheel.

Lubrication: Oil lubrication, see Additional Documents. Oils or other lubricants containing EP additives must not be used.

Temperature range: approx. -10°C to + 50°C.

Other versions on request.

| SKU | d H7 [mm] | D [mm] | B [mm] | d1 [mm] | D1 [mm] | E [mm] | r1 [mm] | b [mm] | t [mm] | b1 [mm] | t1 [mm] | Drehmoment [Nm] | Schleppmoment [Nm] | max. Überholdrehzahl Innenring [min-1] | max. Überholdrehzahl Außenring [min-1] | Gewicht [g] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TFS12 | 12 | 35 | 13 | 18 | 30 | 0,6 | 0,3 | 4 | 1,8 | 4 | 1,4 | 18 | 0,04 | 4500 | 2300 | 68 |

| TFS15 | 15 | 42 | 18 | 22 | 36 | 0,8 | 0,3 | 5 | 1,2 | 5 | 1,8 | 28 | 0,06 | 3500 | 1800 | 120 |

| TFS17 | 17 | 47 | 19 | 22 | 38 | 1,2 | 0,8 | 5 | 1,2 | 5 | 2,3 | 50 | 0,11 | 3200 | 1600 | 150 |

| TFS20 | 20 | 52 | 21 | 27 | 45 | 1,2 | 0,8 | 6 | 1,6 | 6 | 2,3 | 84 | 0,18 | 2500 | 1300 | 220 |

| TFS25 | 25 | 62 | 24 | 35 | 52 | 1,2 | 0,8 | 8 | 2,0 | 8 | 2,8 | 128 | 0,19 | 2000 | 1000 | 360 |

| TFS30 | 30 | 72 | 27 | 40 | 62 | 1,8 | 1,0 | 8 | 2,0 | 10 | 2,5 | 200 | 0,21 | 1600 | 800 | 530 |

| TFS35 | 35 | 80 | 31 | 48 | 70 | 1,8 | 1,0 | 10 | 2,4 | 12 | 3,5 | 475 | 0,42 | 1400 | 700 | 790 |

| TFS40 | 40 | 90 | 33 | 54,5 | 78 | 1,8 | 1,0 | 12 | 2,2 | 12 | 4,1 | 607 | 0,46 | 1300 | 650 | 1050 |

| TFS45 | 45 | 100 | 36 | 59 | 85,3 | 1,8 | 1,0 | 14 | 2,1 | 14 | 4,6 | 756 | 0,56 | 1100 | 550 | 1370 |

| TFS50 | 50 | 110 | 40 | 65 | 92 | 1,8 | 1,0 | 14 | 2,1 | 14 | 5,6 | 1124 | 0,60 | 1000 | 500 | 1900 |

| TFS60 | 60 | 130 | 46 | 84 | 110 | 2,6 | 1,5 | 18 | 2,3 | 18 | 5,5 | 1975 | 0,87 | 840 | 420 | 3110 |