Clamping Bushes E, boreholes 15 - 50 mm

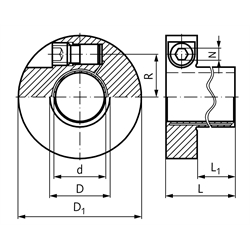

Material: high-quality steel The clamping bush consists of a double-walled steel sleeve filled with a pressure medium, and a flange part. Inside the flange there is a screw and a piston with seal to build up compression. Function: When the thrust screw is tightened, the sleeve expands uniformly against shaft and hub, creating a rigid connection through frictional force. When the thrust screw is loosened, the bush returns to its initial position and can be easily disassembled. Concentricity: 0,02 mm. Tolerances: Shaft h7 for d = 15 mm. Shaft k6-h7 for d = 19, 22, 24, 28, 32, 38 and 48 mm. Shaft h8 for the other diametres d. Hub H7. MN = transmittable torque at load of 0. If the screws are fastened with Manz. Fa = transmittable axial force at torque of 0. If the screws are fastened with Manz. Fr = Maximum transmittable radial force. Manz = required fastening torque for the screws. * with coated surface Temperature range: -30° to +85°C.

Do you have a clamping set with a foreign designation?

Recode it here in our exchange Tool

| SKU | d [mm] | D [mm] | D1 [mm] | L [mm] | L1 [mm] | Transferable Torque MN [Nm] | Transferable Axial Force Fa [k N] | Transferable Radialkraft Fr [k N] | PW [N/mm²] | PN [N/mm²] | Bolts DIN 915, 12.9* Size | R [mm] | N [mm] | Bolts DIN 915, 12.9* Manz [Nm] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 61591500 | 15 | 18 | 46 | 39 | 25 | 46 | 5,1 | 0,5 | 90 | 70 | M10 | 15,1 | 5 | 5 | 0,16 |

| 61591587 | 15,875 | 19 | 47 | 40 | 26 | 53 | 5,5 | 0,5 | 90 | 70 | M10 | 15,6 | 5 | 5 | 0,17 |

| 61591900 | 19 | 23 | 50,5 | 42 | 28 | 85 | 7,3 | 1 | 90 | 70 | M10 | 17,4 | 5 | 5 | 0,2 |

| 61591905 | 19,05 | 23 | 50,5 | 42 | 28 | 85 | 7,3 | 1 | 90 | 70 | M10 | 17,4 | 5 | 5 | 0,2 |

| 61592000 | 20 | 24 | 51,5 | 44 | 30 | 110 | 9,1 | 1 | 90 | 70 | M10 | 18 | 5 | 5 | 0,21 |

| 61592200 | 22 | 27 | 55,5 | 46 | 32 | 130 | 9,6 | 1,2 | 90 | 70 | M10 | 19,3 | 5 | 5 | 0,25 |

| 61592400 | 24 | 29 | 57,5 | 47 | 33 | 190 | 13 | 1,4 | 90 | 70 | M10 | 20,3 | 5 | 5 | 0,27 |

| 61592500 | 25 | 30 | 58 | 49 | 35 | 230 | 15 | 1,5 | 90 | 70 | M10 | 20,8 | 5 | 5 | 0,27 |

| 61592540 | 25,4 | 31 | 59 | 49 | 35 | 190 | 12 | 1,5 | 90 | 70 | M10 | 21,2 | 5 | 5 | 0,29 |

| 61592800 | 28 | 34 | 63 | 52 | 38 | 280 | 16 | 1,8 | 90 | 70 | M10 | 22,6 | 5 | 5 | 0,34 |

| 61593000 | 30 | 36 | 64,5 | 54 | 40 | 380 | 21 | 2 | 90 | 70 | M10 | 23,6 | 5 | 5 | 0,35 |

| 61593175 | 31,75 | 39 | 68,5 | 56 | 42 | 430 | 22 | 2,2 | 90 | 70 | M10 | 24,8 | 5 | 5 | 0,42 |

| 61593200 | 32 | 39 | 68,5 | 56 | 42 | 440 | 22 | 2,2 | 90 | 70 | M10 | 24,8 | 5 | 5 | 0,42 |

| 61593500 | 35 | 42 | 73 | 59 | 45 | 640 | 30 | 2,5 | 90 | 70 | M10 | 26,4 | 5 | 5 | 0,48 |

| 61593800 | 38 | 46 | 84,5 | 72 | 52 | 890 | 38 | 2,8 | 90 | 70 | M16 | 31 | 8 | 21 | 0,84 |

| 61594000 | 40 | 48 | 86,5 | 75 | 55 | 1100 | 45 | 3 | 90 | 70 | M16 | 32 | 8 | 21 | 0,88 |

| 61594500 | 45 | 54 | 93 | 78 | 58 | 1400 | 51 | 3,5 | 90 | 70 | M16 | 34,8 | 8 | 21 | 1,05 |

| 61594800 | 48 | 59 | 97 | 79 | 59 | 1700 | 57 | 4 | 90 | 70 | M16 | 36,8 | 8 | 21 | 1,21 |

| 61595000 | 50 | 60 | 98,5 | 80 | 60 | 1900 | 63 | 4,5 | 90 | 70 | M16 | 37,5 | 8 | 21 | 1,20 |

| 61596000 | 60 | 73 | 115,5 | 90 | 70 | 3300 | 90 | 5,3 | 90 | 70 | M16 | 43,3 | 8 | 21 | 1,85 |